33 Years of ASSY® - Build with timber, built on ASSY® screws.

Testimonials

History of ASSY®

1992

The year everything began with the first ASSY® screw featuring AW recess.

1998

ASSY® Isotop and ASSY®Plus followed, allowing for even more versatile screw connections.

2008

ASSY® 3.0 introduced a further development of the head shape and thread-for more precision and a firm fit in any material.

2020

The launch of the new ASSY® 4 and ASSY®Plus 4 screws brought developments for top performance. The first generation with RW recess for even better load transmission and a tip geometry developed to reduce the splitting effect.

2024

ASSY® 4 PII CSMP. With underhead thread and optimized drill tip, it ensures gap-free tightening of the components, reliable anchoring and maximum protection against over-tightening.

1992

The year everything began with the first ASSY® screw featuring AW recess.

1998

ASSY® Isotop and ASSY®Plus followed, allowing for even more versatile screw connections.

2008

ASSY® 3.0 introduced a further development of the head shape and thread-for more precision and a firm fit in any material.

2020

The launch of the new ASSY® 4 and ASSY®Plus 4 screws brought developments for top performance. The first generation with RW recess for even better load transmission and a tip geometry developed to reduce the splitting effect.

2024

ASSY® 4 PII CSMP. With underhead thread and optimized drill tip, it ensures gap-free tightening of the components, reliable anchoring and maximum protection against over-tightening.

ASSY® Key Features

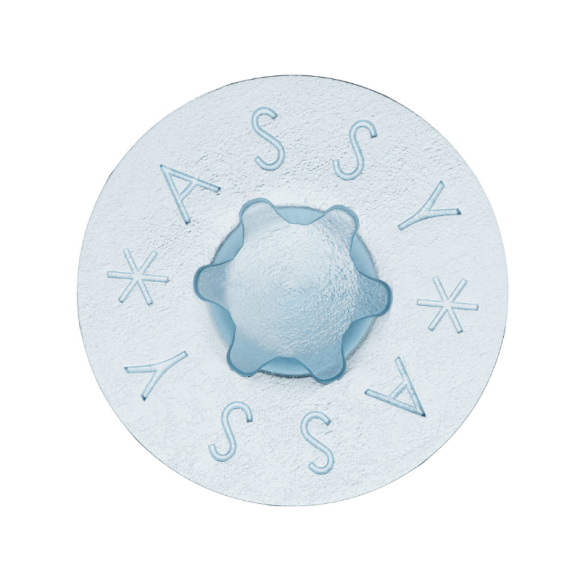

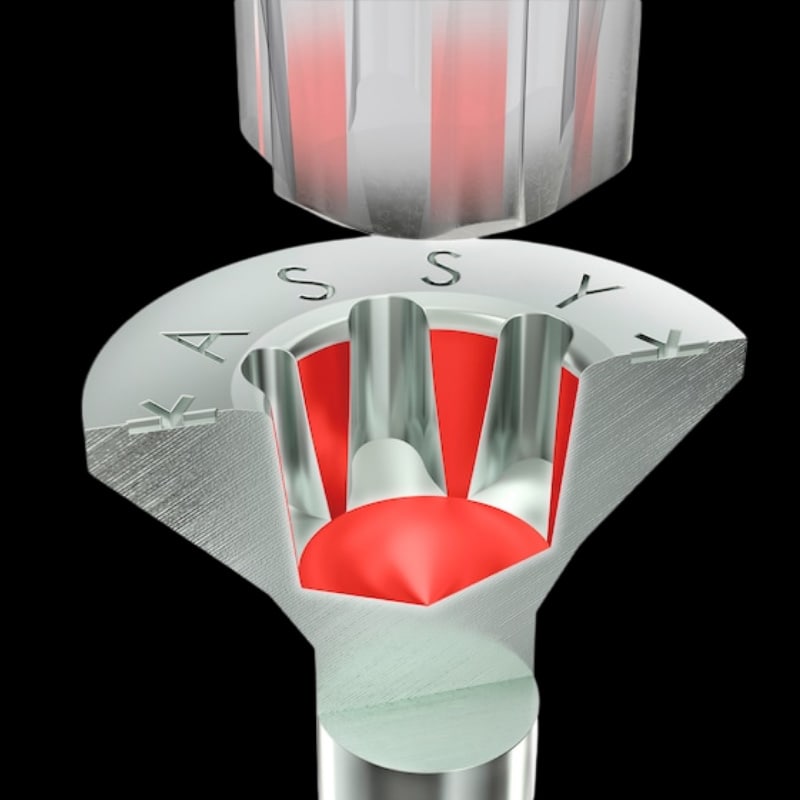

The RW® Recess: Better Grip, More Power

More of everything, but less effort: we improved the process of screwing with the development of the RW recess: The larger contact surface on the bit allows for better load transmission and prevents spinning. Precise positioning without wobbling allows for precise locating of the screw while the tight-fit recess makes working with only one hand possible.

In a nutshell: The RW recess offers more power, stability and efficiency.

Benefits:

- 2 bit sizes for 80 % of applications (RW20 for 3.5 to 5 mm

and RW40 for 5 to 10 mm) - No wobbling

- Highest load transmission

- Compatible with the preceding AW drive

The Evolution of the Underhead Thread

The evolution of the underhead thread allows for a more efficient screwing of components: An improved head pull-through ensures the components are pulled together without any gaps and without having to sink the screw head deep into the material. The combination of asymmetrical single thread and matching thread geometry ensures stable anchoring in timber while minimizing the risk of over-tightening.

Benefits:

- Gap-free joining of the components

- Smaller and less visible screw heads

- The asymmetrical thread reduces the risk of over-tightening

- Reliable anchoring in timber

The Plus Drill Tip: Ideal splitting properties

The development of the PLUS centring drill tip allows for precise positioning and clean spot drilling without tearing the timber. The centring pin also prevents slipping during drilling even on hard materials, allowing for highly precise working. Sharp cutting edges make for a precise drill hole. And due to the smooth thread start, any screwing is done quickly and easily.

Benefits:

- Less splitting

- Small edge distances as pre-drilled

- Close-to-edge screw connections

- Small material cross-sections